Managing heat in electronics requires selecting the right heat sink material. The material should efficiently transfer heat away from components, protecting them and ensuring the device runs smoothly. Aluminum is lightweight and cost-effective, while copper offers superior heat conduction.

The choice depends on your device’s cooling needs, performance requirements, and design constraints. This guide helps you understand which materials provide the best cooling and how to choose the most suitable one for your application.

Key Considerations for Choosing Heat Sink Materials

- Thermal Conductivity: This measures how efficiently a material transfers heat. Materials like copper move heat quickly, keeping electronics cool and improving performance. Materials with low conductivity may cause devices to overheat, reducing their lifespan.

- Density and Weight: The material’s weight affects the device’s design and portability. Lightweight materials like aluminum make devices easier to carry, while heavier materials like copper transfer heat better but make the device heavier.

- Cost and Availability: Material price and accessibility affect production. Rare or expensive materials increase costs and may cause delays, while cheap and readily available materials make manufacturing easier and more efficient.

- Corrosion Resistance: Heat sinks must withstand moisture, chemicals, and other environmental factors. Materials like aluminum or coated metals resist corrosion and maintain performance over time. Corrosion-prone materials can degrade quickly, reducing efficiency and reliability.

- Manufacturability and Design Flexibility: Choose materials that are easy to shape, machine, or mold, as this simplifies production and keeps costs lower. Materials that are hard to work with can make manufacturing more complex and expensive.

- Environmental Conditions: In harsh environments, materials like graphite or composites are often required because they withstand extreme heat, chemicals, and corrosion, though they are generally more expensive.

Considering these factors helps engineers select a heat sink material that provides the best balance of cooling performance, durability, cost, and practicality for their specific application.

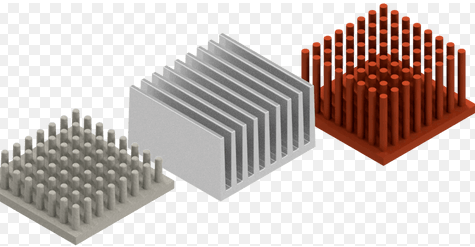

Common Heat Sink Materials

Choosing a heat sink material means balancing thermal performance, weight, cost, and application needs. Here’s an overview of the most widely used options:

- Aluminum

Advantages:

- Lightweight: Aluminum is much lighter than copper, which makes it a better choice for devices where reducing weight is important, such as laptops or aerospace components.

- Cost-Effective: It is cheaper than copper, so it’s more practical for mass production and consumer electronics.

- Corrosion Resistance: Aluminum naturally develops a thin oxide layer on its surface, which protects it from rusting or corroding over time.

- Manufacturability: It can be easily shaped through processes like extrusion, casting, or machining, making it versatile for many heat sink designs.

Limitations:

- Lower thermal conductivity (~150–235 W/m·K) compared to copper.

Applications: Consumer electronics, laptops, LED lighting, and general-purpose cooling.

- Copper

Advantages:

- Superior Thermal Performance: Delivers outstanding heat dissipation for efficient cooling.

- Corrosion Resistance: Highly resistant to rust and corrosion, even in demanding industrial environments.

Limitations:

- Weight: Heavier than aluminum, making it less suitable for weight-sensitive designs.

- Cost: More expensive, which can raise overall product costs.

- Manufacturability: Harder to work with, often requiring advanced machining methods like skiving or milling.

Applications: High-performance CPUs/GPUs, power electronics, servers, industrial systems

- Graphite

Advantages:

- Lightweight: Much lighter than metals, making it easy to use in devices where weight matters.

- Corrosion-Resistant: Doesn’t rust or get damaged by moisture, so it lasts longer.

Limitation:

- Brittle: Can crack or break easily, so it’s not ideal for rough handling.

- Hard to Work With: Difficult to cut, shape, or machine compared to metals.

- Costly: Usually more expensive than metals like aluminum or copper.

- Hybrid Materials (e.g., Copper-Aluminum Composites)

Advantages:

- Balanced Performance: Combines the benefits of different materials to provide good heat transfer while keeping the weight lower than pure copper.

- Cost-Effective: Usually less expensive than using pure copper, making it a practical choice for applications needing strong thermal performance without the high cost.

Limitations:

- Complex Manufacturing: Making these materials often requires advanced techniques, which can be more challenging and time-consuming.

- Material Compatibility: Combining different materials can create weak spots or expand differently under heat, so careful design is needed to prevent issues.

Comparing Material Benefits

A. Aluminum vs. Copper: Weight vs. Thermal Performance

- Thermal Performance:

- Copper: Excellent thermal conductivity (~400 W/m·K), making it highly efficient at transferring heat from components. Ideal for high-performance applications.

- Aluminum: Moderate thermal conductivity (~237 W/m·K). While not as efficient as copper, it can still provide effective cooling, especially with larger surface areas or optimized fin designs.

- Weight Considerations:

- Copper: Dense and heavy, which can be a disadvantage for portable or weight-sensitive devices.

- Aluminum: Lightweight, making it suitable for handheld electronics, laptops, or aerospace applications.

- Cost and Manufacturability:

- Copper: More expensive and harder to machine, which can increase production costs.

- Aluminum: Affordable and easy to manufacture, suitable for mass production.

- Use Cases:

- Copper: Best for high-performance applications like CPUs, GPUs, or high-power LEDs where efficient heat dissipation is critical.

- Aluminum: Ideal for general-purpose electronics where cost, weight, and manufacturability are more important.

This comparison helps you select the best material by considering heat transfer performance, weight limits, and cost.

B. Special Applications: Graphite and Composites

- Graphite:

- Thermal Performance: High thermal conductivity for compact heat management.

- Lightweight: About 70% lighter than aluminum, ideal for weight-sensitive devices.

- Durability: Resistant to corrosion and chemical damage, so it lasts a long time.

- Use Cases: LED lighting, compact electronics, aerospace components.

- Composites:

- Tailored Properties: Combine metals like aluminum with other materials to optimize thermal and mechanical performance.

- Design Flexibility: Can customize thermal conductivity, weight, and strength.

- Use Cases: Automotive electronics, power electronics, high-performance computing.

Choosing the right heat sink material depends on your application. Balance thermal performance, weight, cost, and manufacturability to ensure efficient and reliable cooling.

How to Select the Right Material

- Assess Cooling Requirements:

Determine how much heat your device generates and how efficiently it needs to be dissipated. High-heat components may require materials with superior thermal conductivity, like copper.

- Consider Environmental Conditions and Durability:

Evaluate the operating environment, including temperature extremes, humidity, chemical exposure, or risk of corrosion. Materials like aluminum, graphite, or composites may be better suited for harsh conditions.

- Balance Cost, Weight, and Manufacturability with Performance Goals:

When selecting a heat sink material, it’s important to find the right balance between thermal performance, weight, cost, and ease of manufacturing. The material should:

- Provide sufficient cooling to prevent overheating and maintain device performance.

- Be lightweight if the device needs to be portable or if weight is a design concern.

- Stay within budget, avoiding materials that are unnecessarily expensive for the application.

- It is easy to shape, machine, and produce, ensuring efficient manufacturing and the ability to create the desired design.

By considering all these factors together, you can choose a material that meets performance requirements while remaining practical and cost-effective.

This approach ensures that the chosen material meets the device’s cooling needs while remaining practical and cost-effective.

Conclusion: Best Heat Sink Material for Cooling

The best heat sink material depends on finding the right balance between cooling ability, weight, cost, and durability. Aluminum is light, inexpensive, and works well for most electronics. Copper cools better but is heavier and more costly, making it best for high-performance systems.

Graphite is lightweight and rust-resistant but fragile and expensive, while hybrid materials offer a mix of benefits. By choosing a material that matches the device’s cooling needs, environment, and budget, you can achieve reliable and efficient performance.